Machining

Our in-house, high-performance machine tool, meets the precise requirements needed to produce the high quality parts you demand.

A variety of decorative and non-decorative finishes are offered to customize Dawson products.

Dawson has the ability to apply a number of finishes – decorative and non-decorative – to the products that it produces. Discover the variety of available options below.

For a metal with a unidirectional, decorative finish, produced by graining metal with an abrasive belt.

Polishing and buffing processes are used to smooth surfaces using an abrasive and a work wheel or a leather strap. Polishing is a more aggressive process while buffing is less harsh, leading to a smoother, brighter finish.

A typically non-decorative finish, also known as tumbling or rumbling, is a random finish applied via tumbling in an abrasive medium. The method of deburring is excellent for small laser cut, punched, or machined components.

Also known as abrasive blasting, sandblasting is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove surface contaminants. It can be decorative.

Dawson has a dedicated blasting room with several blasting media options to satisfy all customer needs.

A DA sander operates through a spinning pad mechanism for decorative and non-decorative finishes.

This finish is very uniform and can be easily repaired should any unforeseeable damage occur - scratches or other surface blemishes are easily removed and the factory finish can be restored.

Our in-house, high-performance machine tool, meets the precise requirements needed to produce the high quality parts you demand.

Dawson operates leanly with work stations and equipment arranged to accommodate a one piece flow, for efficient manufacturing and quality assurance.

Reviews, inspections, and tests are regularly conducted at appropriate stages to verify that the requirements have been met.

Our equipment utilizes a superior and more efficient air bending technique for seamless pieces.

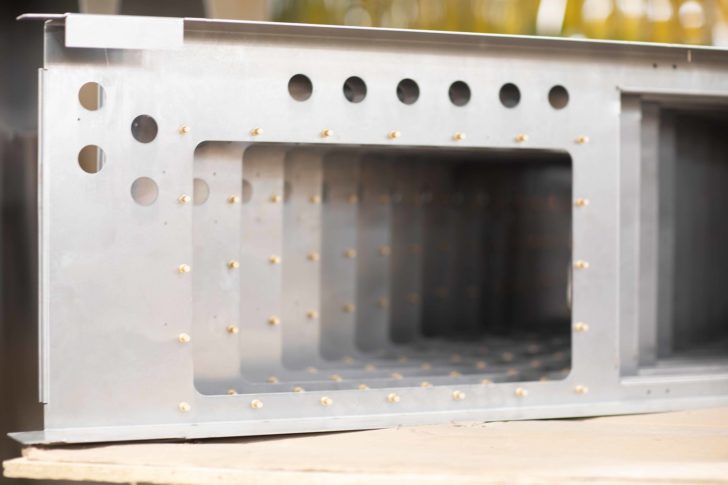

Complex sheet metal component shapes are achieved through precise, programmed machinery.

A full range of mechanical fastening options are available to achieve your project’s requirements.

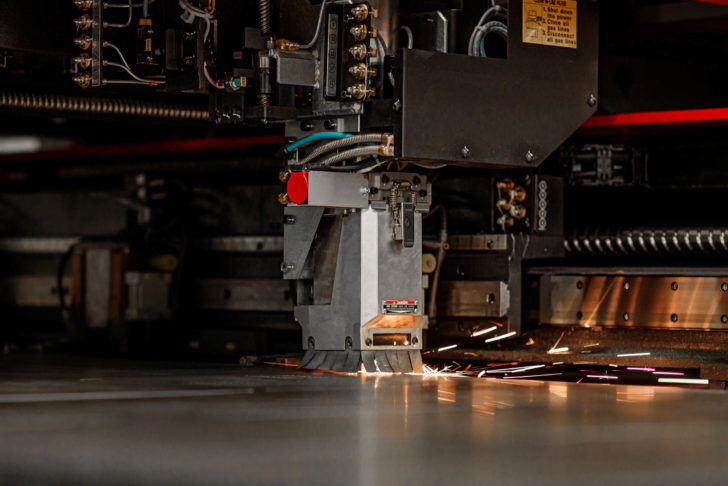

Dawson’s facilities house multiple state-of-the-art lasers, with full sheet stock cutting capabilities.

One of our many welding fabrication techniques are applied to fuse your creation together.