The DAWSON Balanced Door

The DAWSON balanced door serves as its signature, and most long-lasting, achievement.

When it comes to balanced doors, DAWSON is the global manufacturer that vendors prefer above all others. DAWSON incorporates the most innovative technology with exceptional attention to detail, to ensure superior quality.

DAWSON Balanced Doors comply with the strictest building codes and ADA guidelines.

The DAWSON Balanced Door is limitless, available in every Series, alloy and finish we offer.

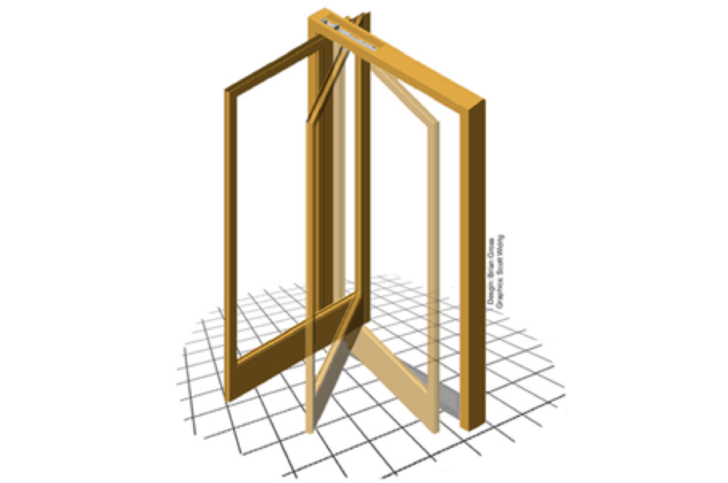

Our top and bottom pivot arms are manufactured from either stainless steel or bronze castings to match the door material.

DAWSON Balanced Doors have been innovatively engineered to house the operating mechanism in the header instead of the floor.

Installation is simple: adjustments are easy; no “groundbreaking” into the floor is required!

What is Balanced?

Balanced doors were originally designed to combat high-wind areas and stack pressure from high-rise buildings. Their design used the differential of interior and exterior air pressure to open the door instead of against it. The hardware helps to balance the weight of the door, allowing part of the door to swing in making it easier to open.

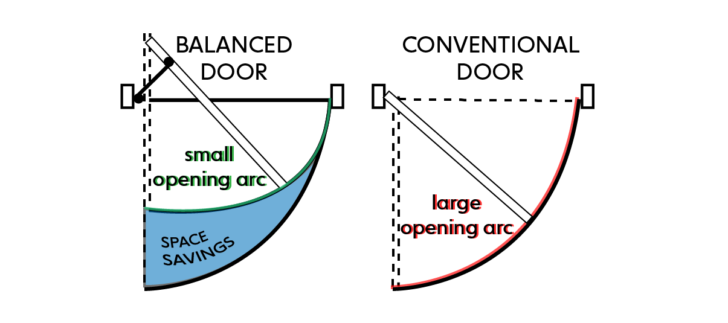

Balanced doors require 1/3 less operational area than conventional doors because of the elliptical motion path they move in. But, even with this reduced space, they’re still very capable of accommodating wheelchairs, shopping carts, and large influxes of visitors.

If spacing is limited, such as in large cities where standard doors would extend beyond property lines, the DAWSON Balanced Door is often the choice for owners and designers.

DAWSON’s Modern auto-operated Available

DAWSON is proud to offer the latest in automatic operated balanced door system.

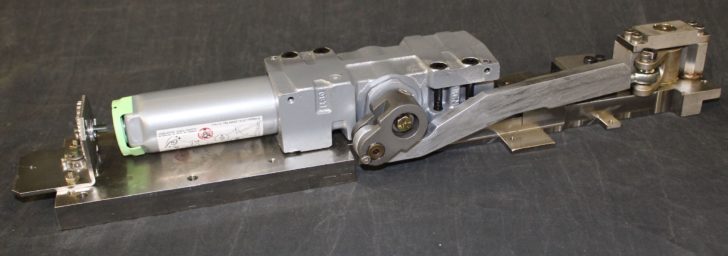

DAWSON’s newly designed system utilizes the Record 8000 series, auto operator. This operator fits nicely in a 6” high x 6” deep header and offers several enhanced features compared to the older, outdated system (still used by our leading competitor).

Our engineers designed this system so that the closer is eliminated from the balanced hardware which creates a truly free swinging door with no resistance.

Next, we designed a smaller robust header mechanism so that the operator’s drive arm could be connected directly to the door. There is a very small cutout on the interior side of the door for the required drive arm clearance, but this is totally concealed when the door is in the closed position.

The Record 8000 series operator features include an internal clutch/brake system that maintains door position at the fully-open and/or fully-closed position. Additionally, a power assist mode is available which provides additional opening force thus greatly reducing the amount of force required to open the door in manual mode (as little as 2 pounds of opening force can be achieved).