DAWSON Engineering Team

At DAWSON we specialize in design for manufacturability, helping our customers save cost and receive product on time

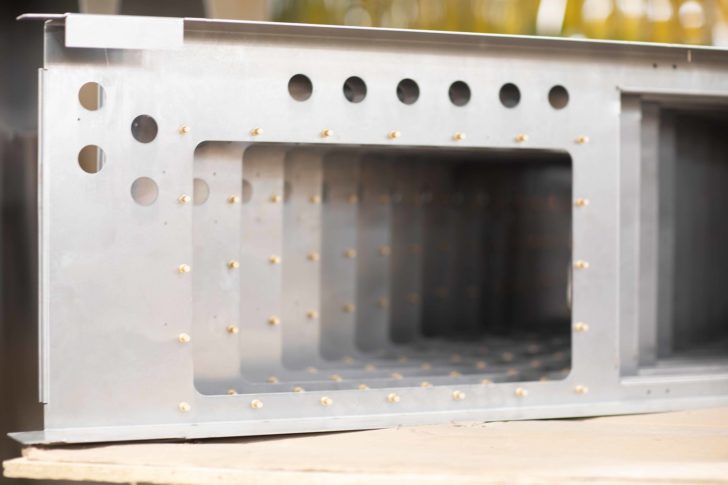

DAWSON has a full range of mechanical fastening options to achieve your project requirements. DAWSON’s capabilities are based on manual and automatic feed systems:

Haeger 824 OneTouch 5e

Haeger 824 Window Touch

Haeger HP6-C

Amada ID40IV HP-NT

This PC-based machine has a Touch-Screen Operator Interface that allows for offline programming effectively reduces cost by saving set up time and providing reliable, repeatable results for self-clinching fastener insertion. The 4 bowl (Auto Feed) offers quick and easy automatic tool change-over between Metric and English fastener types ranging from M3 to 1⁄4-20 in one handling.

This PC-based machine has a Touch-Screen Operator Interface that effectively reduces cost by saving set up time and providing reliable, repeatable results for self-clinching fastener insertion. The multi-shuttle (Auto Feed) offers quick and easy tool change-over between Metric and English fastener types ranging from M3 to 1⁄4-20 in one handling.

DAWSON also maintains two Haeger HP6-C 6 ton manual insertion presses. These presses are used for projects that require large sized fasteners or have five or more unique types, allowing for uninterrupted production runs.

DAWSON utilizes the latest in spot welding technology from Amada for resistance weld nuts and studs.

Ideal when vibration resistance is required.

Provide strong, load-bearing threads.

Economical solution when parts are to be permanently fastened together – before or after finish.

Use for cosmetic appearance, better thread strength than tapped holes, or material that is too thin to tap.

A proven process for attaching metal studs to a workpiece through the use of an electric arc. This process does not require any predrilling or punching of holes and does not mar the opposing side of the material.

At DAWSON we specialize in design for manufacturability, helping our customers save cost and receive product on time

DAWSON’s facilities house multiple state-of-the-art lasers, with full sheet stock cutting capabilities.

Complex sheet metal component shapes are achieved through precise, programmed machinery.

One of our many welding fabrication techniques are applied to fuse your creation together.

Our in-house, high-performance machine tool, meets the precise requirements needed to produce the high quality parts you demand.

Our equipment utilizes a superior and more efficient air bending technique for seamless pieces.

DAWSON operates leanly with work stations and equipment arranged to accommodate a one piece flow, for efficient manufacturing and quality assurance.

Reviews, inspections, and tests are regularly conducted at appropriate stages to verify that the requirements have been met.