DAWSON Engineering Team

At DAWSON we specialize in design for manufacturability, helping our customers save cost and receive product on time

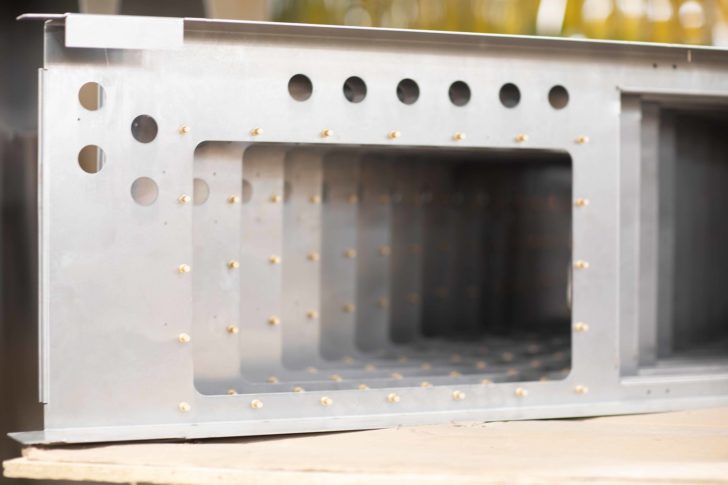

DAWSON utilizes cellular manufacturing for many of its medium to long-term projects. In a cellular manufacturing environment, workstations and equipment are arranged to support the smooth flow of materials and components, controlled quality assurance, and overall reduced process time from start to finish.

Since this process is based upon one-piece flow, this manufacturing method reduces the amount of time for a single product to move from start to finish. The cellular manufacturing method also dramatically reduces waste since products move through the cell one piece at a time.

Defects are quickly detected and addressed, resulting in minimal disruption to the production schedule. In a more conventional approach of batch-and-queue, defects may not be as easily detected before an entire batch is produced.

With improved processes and properly managed time, workflows are smooth and efficient.

With pieces moving through one piece at a time, waste is controlled and minimized.

Defects are quickly detected and addressed for minimal disruption to the production schedule.

At DAWSON we specialize in design for manufacturability, helping our customers save cost and receive product on time

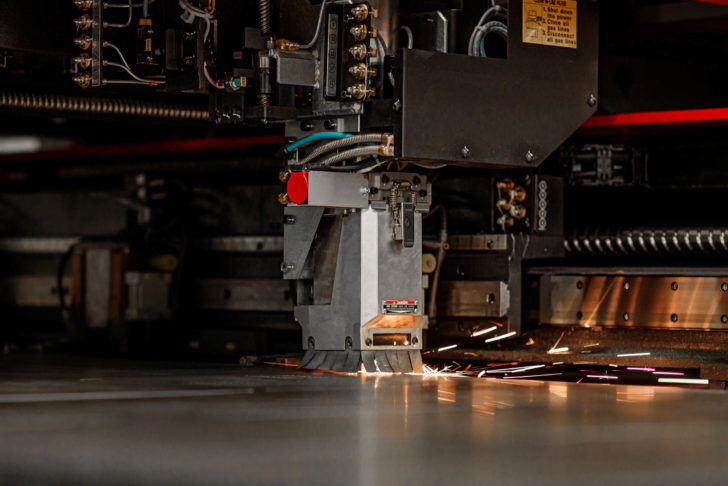

DAWSON’s facilities house multiple state-of-the-art lasers, with full sheet stock cutting capabilities.

Reviews, inspections, and tests are regularly conducted at appropriate stages to verify that the requirements have been met.

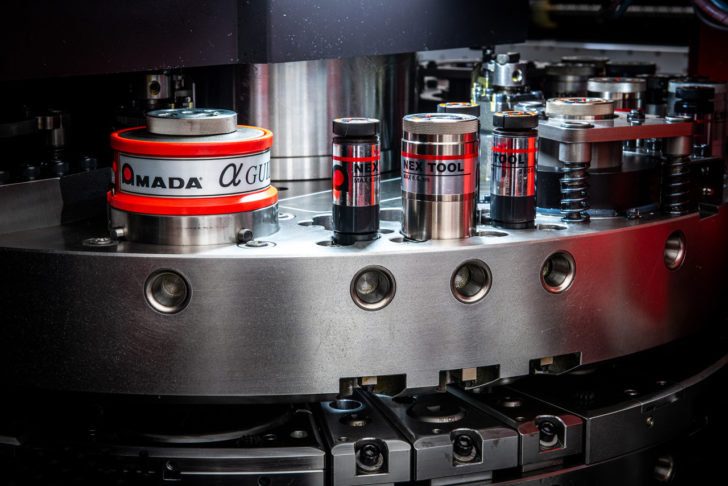

Our equipment utilizes a superior and more efficient air bending technique for seamless pieces.

Complex sheet metal component shapes are achieved through precise, programmed machinery.

One of our many welding fabrication techniques are applied to fuse your creation together.

Our in-house, high-performance machine tool, meets the precise requirements needed to produce the high quality parts you demand.

A full range of mechanical fastening options are available to achieve your project’s requirements.