Thermal Break in Doors: What you need to know!

With increasing federal mandates placed on facility owners to reduce their energy consumption, it’s no surprise that more and more owners and designers are seeking out ways to improve their building’s efficiency. Doors play a vital role in the overall energy efficiency of a building and thermally broken doors are becoming a more demanding application than ever before. This technology is now available in fully customizable sizes and hardware configurations, available in steel, aluminum, and bronze.

What is a thermal break and why is it used in doors?

A thermal break is a barrier or “break” in a window or door frame. Thermally broken door systems are used whenever there is a difference between indoor and outdoor temperatures. Metal is an excellent conductor of heat and cold, meaning that you can lose a great deal of heat through a door frame. Metal has a high thermal conductivity level because thermal energy (heat) moves through the material quickly. A thermal break is created when a material of low thermal conductivity is placed between the door’s conductive materials to stop energy transfer. This thermal break acts as a barrier that reduces heat conduction through the door’s metal framing.

A Thermally Broken Frame features a reinforced polyamide strip fixed between the inside and outside aluminum profiles, creating an insulated barrier within the frame.

Why is a thermal break important?

HEAT LOSS

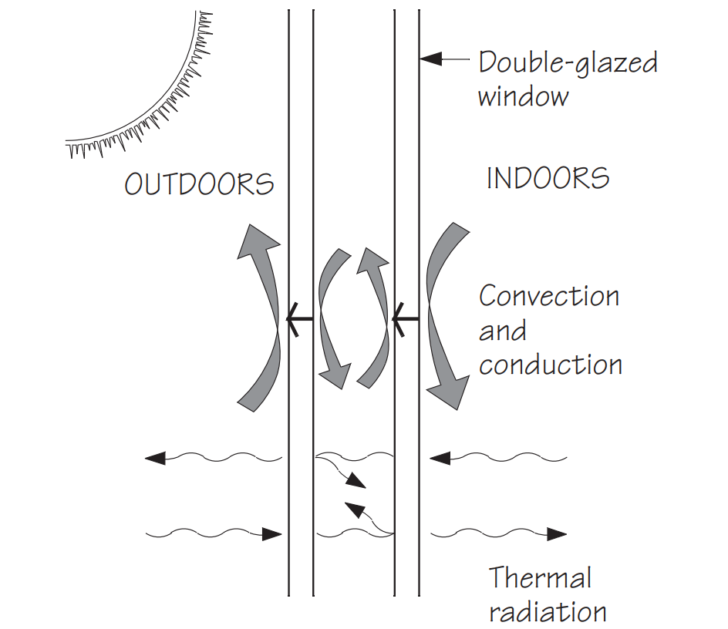

Heat loss in a building is measured by calculating the amount of heat transfer through a building’s envelope from the inside to the outside. It occurs through convection, conduction, radiation, mass transfer, or any combination of these. The most common heat loss methods are the conduction of thermal energy through building components and convection of heat away from the building components into the surrounding air.

A thermal break is crucial for any metal door separating two different climates, i.e., external doors. When the outside of the door gets cold, the door’s metal framing will conduct heat to the inside surface of the door. The door, in this case, is bringing the cold directly into your building through conduction. This will cause condensation and frost to build up on the inside of the door. The cold inside surface of the door will then be exposed to the warm air inside the building. As the warm air passes over the surface of the door, it is cooled and will transport heat into the rest of your building through the natural convection currents that occur in the airspace.

Thermal breaks are essential for metal door systems as it separates the frame into two separate pieces – exterior and interior. This separation allows for a less conductive material to be placed between the components and significantly reduces temperature transfer, and aids in achieving modern thermal performance levels. Minimizing this transfer will not only save money, but it reduces a building’s overall carbon footprint while improving occupant comfort.

A thermal break can reduce heat loss by 50% and give you the energy-efficient door you desire.

CONDENSATION

When non-thermally broken systems are used between different interior/exterior climates, the metal frame’s internal face will remain cold as it transfers its internal heat outside. Condensation will form on this cold inner surface that can cause frost build-up and damage to the material finish. Over time as the water leaks down the door into the floor and surrounding areas, larger problems could arise, such as water damage.